In the electronics field, temperature monitoring and control play a crucial role. The diode NTC (Negative Temperature Coefficient) thermistor is one of the key components for this purpose. This article will explore more details about the diode NTC thermistor, including the working principles, applications, benefits, and other aspects.

What is a Diode NTC Thermistor?

A diode NTC thermistor is a type of temperature sensor that exhibits a negative temperature coefficient. It is composed of a highly sensitive semiconductor material, typically made of metal oxides, that allows the electrical resistance to decrease as the temperature increases. This unique characteristic makes it a valuable component in various temperature sensing and control applications.

Working Principle of Diode NTC Thermistors

Diode NTC thermistors operate on the basis of the relationship between temperature and electrical resistance. As the temperature rises, the semiconductor material within the thermistor experiences a higher rate of thermal excitation, resulting in the movement of charge carriers. This movement leads to a decrease in electrical resistance, allowing the thermistor to measure and respond to temperature changes accurately.

Types of Diode NTC Thermistors

Several types of diode NTC thermistors are available, each with unique properties and applications. Some common types include:

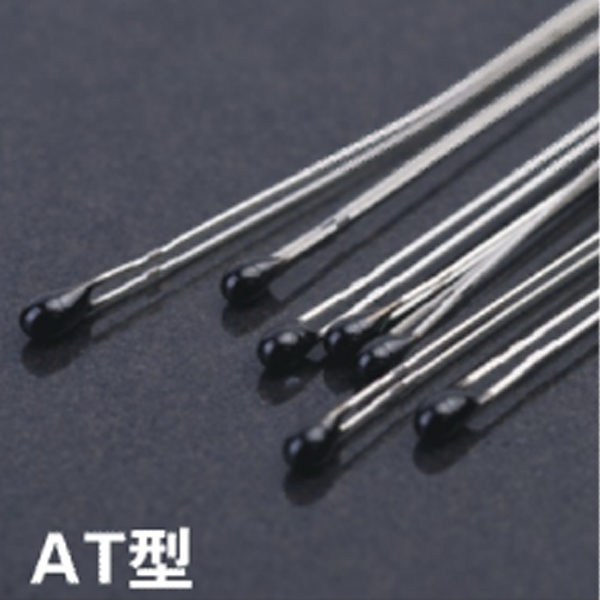

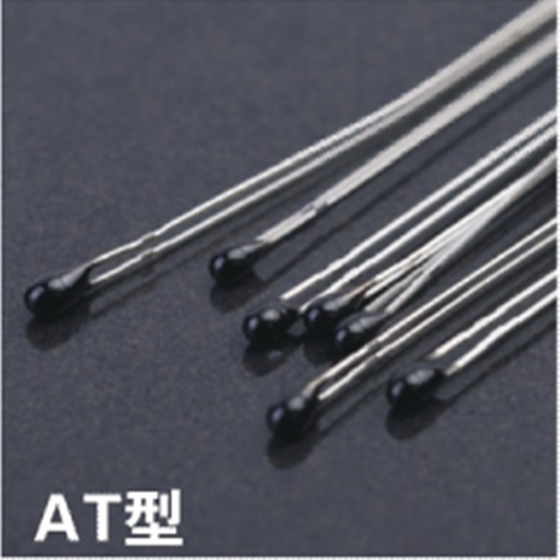

Glass-Encapsulated Diode NTC Thermistors

Glass NTC thermistors are encased in a glass package, providing protection against environmental factors such as moisture and contaminants. They are widely used in applications that require high accuracy and reliability, such as temperature sensing in automotive systems and medical devices.

Surface-mount Diode NTC Thermistors

Surface-mount diode NTC thermistors are designed for easy integration onto printed circuit boards (PCBs). They are compact in size and offer fast response times, making them suitable for applications where space is limited, such as portable electronics and consumer appliances.

Probe-Style Diode NTC Thermistors

Probe-style thermistors feature a long, slender design with a sensing element at the tip. They are commonly used for temperature monitoring in liquids and gases, as their shape allows for easy immersion and extraction.

Advantages of Diode NTC Thermistors

Diode NTC thermistors offer several advantages over other temperature-sensing technologies.

High sensitivity: Diode NTC thermistors exhibit a highly sensitive response to temperature changes, enabling accurate and precise measurements.

Wide temperature range: They can operate over a wide temperature range, making them suitable for both low- and high-temperature applications.

Fast response time: Diode NTC thermistors provide rapid response times, allowing for real-time temperature monitoring and control.

Cost-effective: Compared to other temperature sensing solutions, diode NTC thermistors are often more cost-effective, making them a preferred choice in many industries.

Applications of Diode NTC Thermistors

Diode NTC thermistors find application in various industries and systems.

Heating, ventilation, and air conditioning (HVAC) systems: Diode NTC thermistors are used for temperature monitoring and control in HVAC systems to ensure optimal performance and energy efficiency.

Automotive industry: They play a crucial role in automotive applications, such as engine temperature monitoring, cabin climate control, and battery management.

Medical devices: Diode NTC thermistors are utilized in medical devices for accurate temperature measurements, such as in fever detection and patient monitoring systems.

Industrial process control: They are employed in industrial processes to monitor and regulate temperatures in manufacturing equipment, chemical processes, and food storage.

Choosing the Right Diode NTC Thermistor

When selecting a diode NTC thermistor for a specific application, several factors should be considered:

Temperature range: Ensure that the selected thermistor can operate within the required temperature range of the application.

Accuracy and precision: Evaluate the thermistor's accuracy and precision specifications to ensure reliable temperature measurements.

Response time: Consider the response time requirements of the application, especially if it involves dynamic temperature changes.

Packaging and form factor: Choose a thermistor package and form factor that aligns with the mechanical and spatial constraints of the application.

Installation and Usage Considerations

To maximize the performance and longevity of diode NTC thermistors, certain installation and usage considerations should be followed:

Avoid mechanical stress: Handle the thermistor with care to prevent mechanical stress, as it can affect its electrical properties.

Proper thermal coupling: Ensure good thermal coupling between the thermistor and the object being measured to achieve accurate temperature readings.

Avoid excessive currents: Do not subject the thermistor to excessive currents, as it can lead to self-heating and inaccurate temperature measurements.

Calibration and periodic testing: Regularly calibrate and test the thermistor to maintain accuracy and detect any potential drift or malfunction.

Testing and Calibration of Diode NTC Thermistors

Testing and calibration are essential to ensure the accuracy and reliability of diode NTC thermistors. The following steps can be taken:

Use a reference temperature source: Compare the readings of the thermistor with a known reference temperature source to verify its accuracy.

Thermal stability testing: Subject the thermistor to varying temperature conditions and monitor its response to ensure stability and consistency.

Calibration adjustment: If necessary, perform calibration adjustments to align the thermistor's readings with the reference temperature source.

Common Challenges and Troubleshooting Tips

While diode NTC thermistors are highly reliable, certain challenges may arise. Here are some common challenges and troubleshooting tips.

Self-heating effects: Excessive self-heating can affect the accuracy of temperature measurements. Avoid high current or voltage applications that may lead to self-heating.

Aging and drift: Thermistors may experience aging and drift over time, leading to inaccurate readings. Regular calibration and replacement, if needed, can mitigate this issue.

Environmental factors: Environmental conditions such as moisture, dust, and chemicals can impact the performance of thermistors. Ensure appropriate protection and sealing if exposed to such conditions.

Industry Trends and Future Developments

The field of temperature sensing is constantly evolving, and diode NTC thermistors are no exception. Some notable trends and future developments include:

Miniaturization: Continued miniaturization of diode NTC thermistors to meet the demands of compact electronic devices and IoT applications.

Enhanced accuracy: Advancements in manufacturing processes and materials to achieve higher accuracy and stability in temperature measurements.

Integration with IoT: Integration of diode NTC thermistors with IoT platforms for remote monitoring, data analysis, and predictive maintenance.

Smart temperature control systems: Developing smart temperature control systems that utilize diode NTC thermistors for efficient and automated temperature regulation.

Conclusion

Diode NTC thermistors are essential for temperature monitoring and control systems across various industries. As technology advances, diode NTC thermistors are expected to play an increasingly vital role in achieving precise and efficient temperature management. If you are looking for further information about the diode NTC thermistor products, please feel free to contact us at engineer@horlechina.com/horle@263.net.