In the intricate world of temperature sensing, NTC (Negative Temperature Coefficient) thermistors serve as indispensable components in a wide range of applications. These precision-engineered devices exhibit predictable resistance changes in response to temperature fluctuations, making them ideal for monitoring and control systems. However, their effectiveness is only as good as their durability, particularly in environments characterized by extreme temperatures, humidity, or corrosive elements.

To combat these challenges, glass-encapsulated NTC thermistors emerge as the superior choice for long-term stability. Encasing the delicate thermistor in a hermetic glass seal enhances its resilience, shielding it from environmental degradation while maintaining its precision over extended periods. This article explores the science behind NTC thermistors, the advantages of glass encapsulation, and the real-world applications where these components thrive under duress.

The Science Behind NTC Thermistors

At their core, NTC thermistors operate on a fundamental principle: as temperature increases, their electrical resistance decreases in a highly predictable manner. This behavior, dictated by the thermistor’s material composition, enables precise temperature measurement in applications requiring exceptional accuracy.

The thermistor itself is typically composed of metal oxides such as manganese, nickel, cobalt, and copper. These oxides are carefully sintered into a ceramic body, forming a structure that exhibits a stable and repeatable resistance-temperature relationship. The predictability of this relationship makes NTC thermistors invaluable in safety-critical systems where even minor temperature variations must be detected and managed with precision.

Why Glass Encapsulation Matters

The effectiveness of an NTC thermistor is not solely determined by its internal composition; its external protection plays an equally crucial role. Glass encapsulation provides an array of advantages that enhance both durability and accuracy.

- Environmental Shielding: A hermetic glass seal prevents contaminants such as dust, moisture, and corrosive gases from degrading the thermistor’s performance over time.

- Chemical Resistance: Unlike polymer-based encapsulants, glass does not react with aggressive chemicals, making it suitable for medical, automotive, and industrial applications.

- Mechanical Robustness: In environments prone to vibration or mechanical stress, glass-encapsulated thermistors remain structurally intact, ensuring long-term operational reliability.

By mitigating these external risks, glass-encapsulated NTC thermistors maintain their precision in conditions where conventional thermistors would degrade or fail prematurely.

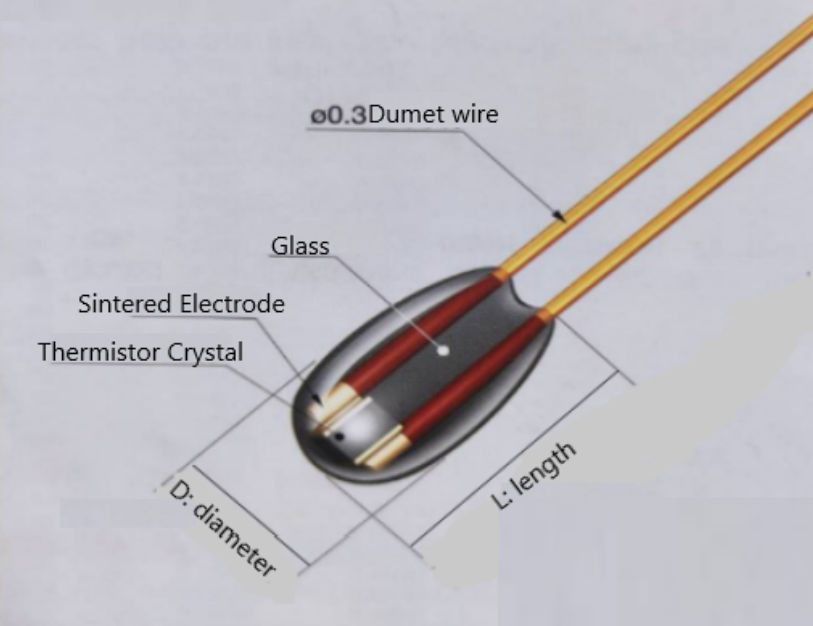

Glass Encapsulated NTC Thermistor

Performance in Extreme Conditions

Glass-encapsulated NTC thermistors distinguish themselves through their ability to endure and perform reliably in severe conditions.

- High-Temperature Endurance: These thermistors operate effectively in extreme thermal environments, maintaining stability even when exposed to temperatures exceeding 200°C. This makes them ideal for automotive engine sensors, industrial furnaces, and aerospace applications.

- Humidity and Corrosion Resistance: The hermetic glass seal acts as a moisture barrier, preventing water ingress that could otherwise cause resistance drift or failure. This feature is critical in HVAC systems, medical devices, and outdoor instrumentation.

- Longevity and Stability: Unlike other thermistor types, glass-encapsulated variants exhibit minimal long-term drift, ensuring consistent performance over years of operation with negligible calibration requirements.

These factors make them indispensable in applications where precision and reliability are paramount.

Comparing Glass NTC Thermistors to Other Encapsulation Methods

While alternative encapsulation techniques exist, they often fall short in harsh conditions:

- Epoxy-coated Thermistors: Although epoxy coatings offer some degree of protection, they are susceptible to moisture absorption, leading to performance degradation over time.

- Polymer-based Encapsulation: Some thermistors use polymer coatings, but these materials can deteriorate due to UV exposure, chemical interactions, or thermal cycling.

- Hermetic Glass Sealing: Glass-encapsulated NTC thermistors outperform these alternatives by providing a robust, moisture-impermeable barrier that ensures long-term accuracy and stability.

The superiority of glass encapsulation becomes evident when considering applications where reliability over decades—not just years—is essential.

Applications Benefiting from Glass NTC Thermistors

Glass NTC thermistors find applications in numerous industries where precision temperature measurement is critical:

- Automotive Sector: Used in engine temperature sensors, battery management systems for electric vehicles, and climate control units, ensuring optimal performance and safety.

- Medical Devices: Essential in blood analyzers, incubators, and respiratory equipment, where even slight temperature variations can impact patient health.

- Industrial Systems: Utilized in process control, power generation, and HVAC systems to maintain efficiency and operational integrity in challenging environments.

These applications highlight the adaptability and resilience of glass-encapsulated thermistors, making them an optimal choice for industries that demand unwavering performance.

Conclusion

Glass-encapsulated NTC thermistors stand as a testament to engineering ingenuity, offering unparalleled stability in the face of environmental challenges. Their ability to withstand extreme temperatures, resist chemical degradation, and maintain long-term precision positions them as the preferred solution for mission-critical applications.

As technological advancements continue to push the boundaries of innovation, the role of reliable temperature sensors will only become more crucial. Selecting the right thermistor—one designed for endurance—ensures both efficiency and longevity in the most demanding conditions.