When it comes to precise temperature measurement in industrial applications, choosing the right sensing technology is crucial. Glass NTC thermistors have emerged as a leading solution, offering unique advantages over other temperature sensing options. This comprehensive guide will explore how glass NTC thermistors compare to alternative technologies, helping you determine the best fit for your specific needs.

What Are Glass NTC Thermistors?

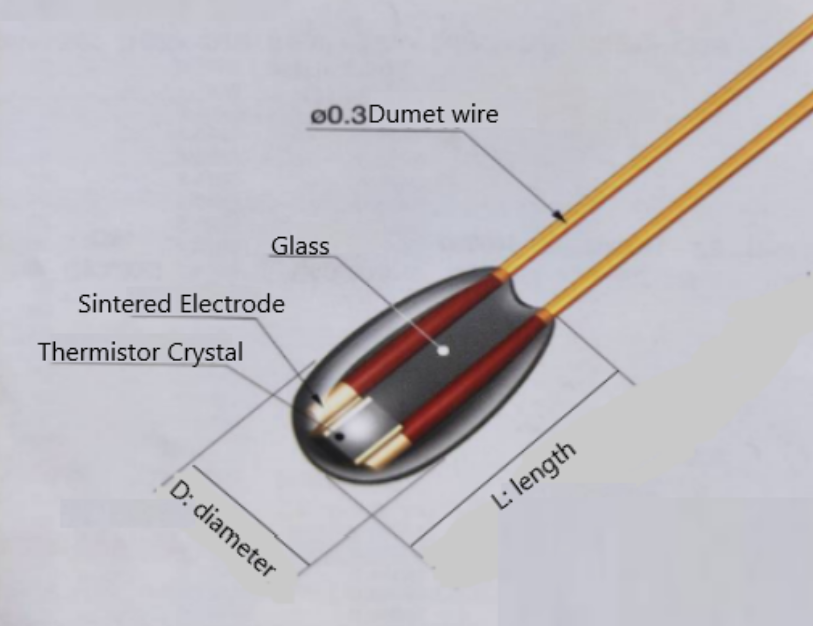

Glass NTC thermistors are specialized temperature sensors that utilize a negative temperature coefficient (NTC) material encapsulated in a glass envelope. This construction provides excellent stability, accuracy, and responsiveness across a wide temperature range. The glass encapsulation offers superior protection against environmental factors, making these sensors ideal for demanding industrial applications.

Key Advantages of Glass NTC Thermistors

High Accuracy: Glass NTC thermistors can achieve accuracies of ±0.1°C or better, surpassing many other sensor types.

Fast Response Time: The small size and low thermal mass of glass NTC thermistors allow for rapid temperature change detection.

Wide Temperature Range: Typically operational from -55°C to +300°C, covering most industrial needs.

Excellent Stability: Glass encapsulation minimizes drift over time, ensuring long-term measurement reliability.

Resistance to Harsh Environments: The glass casing provides superior protection against moisture, chemicals, and mechanical stress.

Comparing Glass NTC Thermistors to Other Technologies

Glass NTC Thermistors vs. Thermocouples

Thermocouples are widely used due to their simplicity and broad temperature range. However, glass NTC thermistors offer several advantages:

Higher Accuracy: Glass NTC thermistors provide significantly better accuracy, especially at lower temperatures.

No Cold Junction Compensation: Unlike thermocouples, glass NTC thermistors don't require complex compensation circuitry.

Better Stability: Glass NTC thermistors exhibit less drift over time compared to thermocouples.

Glass NTC Thermistors vs. RTDs (Resistance Temperature Detectors)

RTDs, particularly platinum RTDs, are known for their excellent accuracy and stability. However, glass NTC thermistors have some distinct benefits:

Faster Response Time: The smaller size of glass NTC thermistors allows for quicker temperature change detection.

Higher Sensitivity: Glass NTC thermistors offer greater resistance change per degree, enabling more precise measurements.

Lower Cost: Generally, glass NTC thermistors are more cost-effective than high-precision RTDs.

Glass NTC Thermistors vs. Semiconductor Sensors

While semiconductor sensors like integrated circuit (IC) temperature sensors offer good linearity and easy integration, glass NTC thermistors excel in:

Wider Temperature Range: Glass NTC thermistors can operate at much higher temperatures than most semiconductor sensors.

Higher Accuracy: Especially when calibrated, glass NTC thermistors can achieve superior accuracy.

Better Stability: Glass encapsulation provides excellent long-term stability compared to many semiconductor options.

Applications Where Glass NTC Thermistors Shine

Glass NTC thermistors are particularly well-suited for applications requiring:

High Precision Measurements: In medical equipment, scientific instruments, and calibration systems.

Harsh Environment Operation: For industrial processes, automotive sensors, and outdoor equipment.

Fast Response Times: In HVAC systems, food processing, and safety-critical applications.

Long-Term Stability: For long-duration monitoring in environmental sensors and industrial control systems.

Choosing the Right Glass NTC Thermistor

When selecting a glass NTC thermistor for your application, consider the following factors:

Temperature Range: Ensure the sensor covers your required operating temperatures.

Accuracy Needs: Determine the level of precision necessary for your measurements.

Response Time: Consider how quickly the sensor needs to detect temperature changes.

Environmental Conditions: Assess the sensor's ability to withstand your application's specific environmental challenges.

Size Constraints: Evaluate whether the sensor's dimensions fit your design requirements.

Conclusion: The Versatility of Glass NTC Thermistors

Glass NTC thermistors offer a compelling combination of accuracy, stability, and environmental resistance that makes them ideal for a wide range of industrial and scientific applications. While other sensing technologies have their place, the unique properties of glass NTC thermistors often make them the superior choice for demanding temperature measurement tasks.

By carefully considering your specific application requirements and leveraging the strengths of glass NTC thermistors, you can ensure precise, reliable temperature sensing in even the most challenging environments. As technology continues to advance, these versatile sensors are likely to play an increasingly important role in temperature measurement across various industries.

For custom glass NTC thermistor solutions tailored to your unique needs, consider partnering with a reputable manufacturer like Horle. With expertise in designing and producing high-quality glass NTC thermistors, we can help you optimize your temperature-sensing capabilities and drive innovation in your applications.