In this article, we'll explore the chip sorting machine and its various applications. We'll take a look at how these machines work, the benefits they offer, and some of the frequently asked questions surrounding them. So, let's dive in!

How Chip Sorting Machines Work

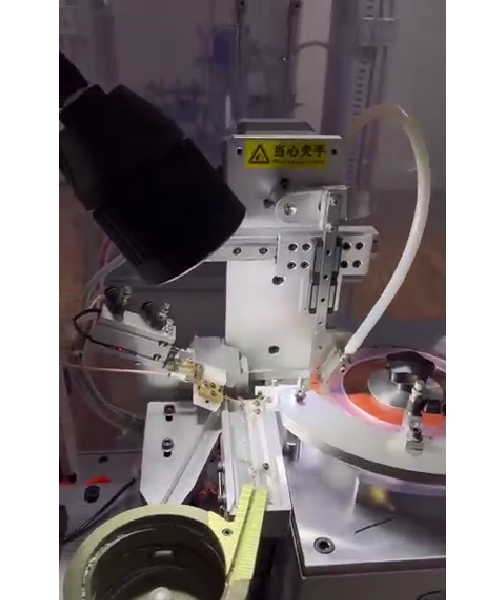

Chip sorting machines use advanced imaging and processing techniques to sort semiconductor chips. The process begins by loading a tray of unsorted chips into the machine. The machine then uses high-resolution cameras to capture images of each chip, analyzing its size, shape, and color.Using this data, the machine then sorts the chips into different categories based on their specifications. For example, the machine can sort chips based on their size, color, or the number of transistors they contain.

Once the sorting process is complete, the machine then packages the chips into trays or tubes, ready for use in manufacturing.

Benefits of Using Chip Sorting Machines

Using a chip sorting machine offers a range of benefits for manufacturers. Here are just a few of the advantages they offer:Increased efficiency: By automating the sorting process, chip sorting machines can sort chips at a much faster rate than humans can. This leads to a significant increase in efficiency, which can save manufacturers time and money.

Improved accuracy: Chip sorting machines use advanced imaging techniques to analyze the chips, leading to a much more accurate sorting process. This means that manufacturers can be confident that they're getting the right chips for their specific needs.

Cost savings: By improving efficiency and accuracy, chip sorting machines can help manufacturers save money on labor costs and reduce waste.

Increased production capacity: Chip sorting machines can sort chips at a much faster rate than humans can, which can help manufacturers increase their production capacity.

Applications of Chip Sorting Machines

Chip sorting machines have a range of applications in the manufacturing industry. Here are just a few examples:Semiconductor manufacturing: Chip sorting machines are commonly used in semiconductor manufacturing, where they're used to sort chips based on their specifications.

Electronics manufacturing: Chip sorting machines can also be used in electronics manufacturing, where they're used to sort components such as resistors, capacitors, and transistors.

Medical device manufacturing: Chip sorting machines can be used in medical device manufacturing to sort chips used in devices such as pacemakers and defibrillators.

Frequently Asked Questions

Here are some of the most frequently asked questions about chip sorting machines:Q: How accurate are chip sorting machines?

A: Chip sorting machines use advanced imaging techniques to analyze the chips, leading to a much more accurate sorting process than manual sorting.

Q: How fast can chip sorting machines sort chips?

A: The speed of chip sorting machines varies depending on the model, but they can typically sort chips at a rate of several hundred per minute.

Q: Can chip sorting machines be customized to sort specific types of chips?

A: Yes, chip sorting machines can be customized to sort chips based on specific criteria such as size, color, or the number of transistors.

Q: Are chip sorting machines expensive?

A: The cost of chip sorting machines varies depending on the model and manufacturer, but they can be a significant investment for manufacturers.