The chip in glass NTC thermistor is a promising technology for temperature sensing and control thanks to its compact size, high accuracy, and low cost. They are already widely used in various industries, and their demand is expected to grow in the coming years. In this article, we will explore the technology behind chip in glass NTC thermistors and how they are revolutionizing temperature sensing in various industries.

What Is The Chip In Glass NTC Thermistor?

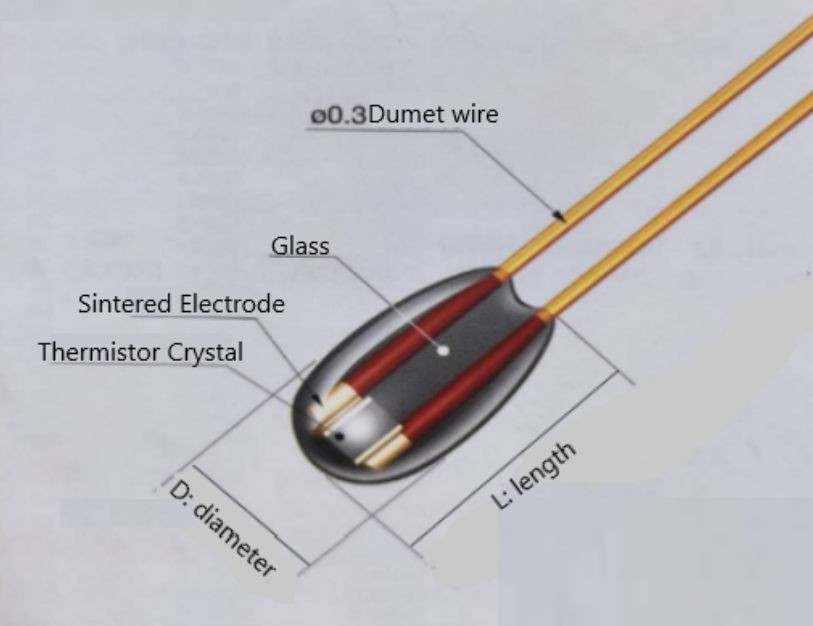

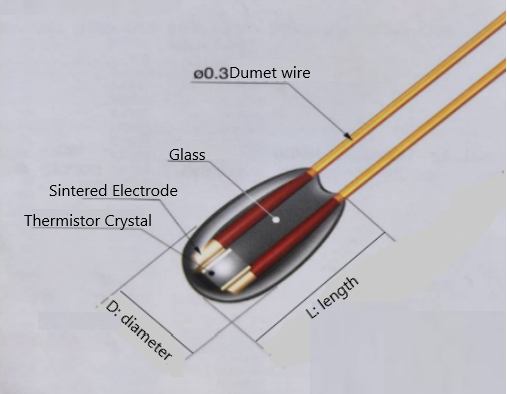

The chip in glass NTC thermistor is an NTC thermistor encapsulated in glass. The thermistor element is a tiny chip made of a ceramic material containing metal oxides. The chip is then encapsulated in glass using a proprietary process to ensure high accuracy, reliability, and stability. The glass material protects the chip from mechanical stress, moisture and other environmental factors that can affect its performance.

Advantages Of Chip In Glass NTC Thermistors

Compact Size For Limited Space

One of the most significant advantages of chip glass NTC thermistors is their small size. They can be suitable for applications where space is limited since they are tiny. This compact design makes the chip in glass NTC thermistor ideal for small electronic devices, such as wearables or medical devices, where size and weight are key factors.

High Accuracy and Stability Over a Wide Temperature Range

The chip in glass NTC thermistor is known for its high accuracy and stability over a wide temperature range. The encapsulation process ensures that the sensor is protected from external factors, including moisture and dust, which can affect its accuracy. This makes them ideal for use in harsh environments, where temperature fluctuations are common.

Fast Response Time for Quick Temperature Changes

Due to their small size, the chip in glass NTC thermistor has a fast response time. They can detect temperature changes quickly and respond accordingly, making them ideal for applications that require quick temperature measurements. This feature is particularly useful in industrial settings where precision and speed are critical factors.

Wide Temperature Range for Diverse Applications

Another significant advantage of the chip in glass NTC thermistor is its ability to measure temperatures over a wide range. They can accurately measure temperatures from -50°C to +300°C, making them suitable for use in various applications, from refrigeration systems to high-temperature industrial processes.

Cost-effective Solution for Temperature Sensing

The mass production of the chip in glass NTC thermistor makes them an affordable option for temperature sensing. They are cost-effective compared to other types of temperature sensors, making them an attractive choice for applications where multiple sensors are required.

Applications Of Chip In Glass NTC Thermistors

Automotive Industry

The chip in glass NTC thermistor is widely used in the automotive industry for various applications. In engine management systems, these sensors can detect the temperature of the engine and provide feedback to the control system for better performance and efficiency. They are also used in climate control systems to regulate the temperature inside the car and in battery management systems to monitor the temperature of the battery.

Medical Industry

In the medical industry, the chip in glass NTC thermistor is used for temperature monitoring of blood, vaccines, and pharmaceuticals. These sensors ensure that the temperature remains within the safe range, and any deviation can be detected quickly, preventing spoilage or damage to the products.

Consumer Electronics

The chip in glass NTC thermistor is commonly found in consumer electronics such as mobile devices, laptops, and home appliances. These sensors are used for temperature control and monitoring in electronic devices to prevent overheating, which can cause damage to the components or reduce the lifespan of the device.

Industrial Applications

In industrial applications, the chip in glass NTC thermistor is used for process control, HVAC systems, and refrigeration systems. These sensors can accurately measure the temperature of a particular process or environment and provide feedback to the control system for better efficiency and performance.

Future Of The Chip In Glass NTC Thermistor

The demand for temperature sensing technology is expected to grow in the coming years, driven by the increasing need for accurate and reliable temperature measurements in various industries. The chip in glass NTC thermistor is well-positioned to meet this demand thanks to its compact size, high accuracy, and low cost. Advances in encapsulation technology and calibration methods are also expected to further improve the performance of chip in glass NTC thermistors in the future.

How To Choose The Right Chip In Glass NTC Thermistor

Choosing the right chip in glass NTC thermistor depends on several factors, including the temperature range, accuracy requirements, and environmental conditions of the application. It is important to select a thermistor that has been calibrated and compensated for the specific temperature range and environmental conditions of the application. The manufacturer's datasheet provides detailed information on the specifications and performance characteristics of the thermistor.

Installation & Maintenance

Installing and maintaining chip in glass NTC thermistors is relatively straightforward. The thermistor can be mounted on the surface of the object being measured using adhesive or mechanical fixtures. It is important to ensure good thermal contact between the thermistor and the object being measured to minimize thermal resistance and improve accuracy. Regular calibration and maintenance are also important to ensure consistent and reliable performance.

Conclusion

If you're looking for a compact, accurate, and cost-effective temperature-sensing solution, the chip in glass NTC thermistor is an excellent choice. With their fast response time and wide temperature range, they can be used in a range of applications, from wearables to industrial processes.