MEDICAL WIRE

Conductor: silver plated copper wire

Conductor field: awg36- awg10

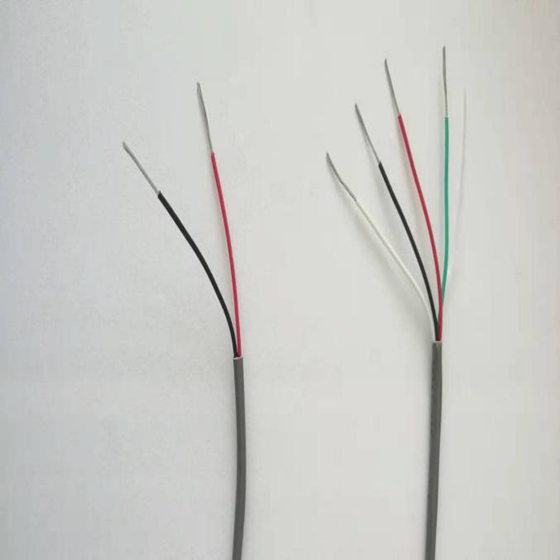

Construction:2-19 cores

Inner wire insulation material: FEP,ETFE,PTFE,ETFE

Jacket: silicone rubber/TPU

Rated temperature: -60- 200℃ Rohs & reach compliance Medical grade with material certificate

Color: red,yellow,bue, white,black,yellow green,brown etc

Using for : medical equipment

PRODUCT DETAILS of Medical Wire:

1.Jacket silicon was made special treatment, no adhesion to dust,and all silicon is odorless.

2.Medical grade: jacket material silicon are medical grade with certificate.

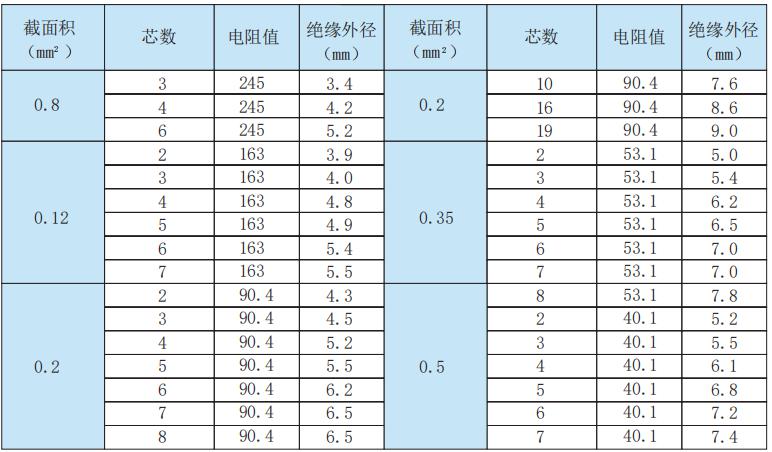

MEDICAL SURGICAL EQUIPMENT WIRE LIST:

(PLEASE NOT: BELOW WIRE SHEET IS OUR NORMAL CONSTRUCTION WIRE, JUST FOR CUSTOMER REFERENCE, WE CAN PROVIDE THE WIRE AS PER CUSTOMER DESIGN)

This wire is very special for insulation material: medical grade silicon, this silicon is odorless and medical grade (with silicon medical grade certificate), silicon jacket surface was made special treatment,silicon jacket surface is dry and no-adhesion to dust, and wire is very soft for twist and easy handle, wire are widely used for medical equipment, most this wire are specially produced as per customer design.

Modern medical electronics require Advanced Medical Wire and Cable that meets stringent specifications. At HORLE Systems, Inc. we take pride in providing our customers with the finest quality custom manufactured medical wire and cable. For use in critical applications such as endoscopes, EKG patient cables, electrosurgical instruments, MRI imaging, ultrasound equipment and more.

HORLE Systems custom manufactures Medical Wire with High-Performance Insulation that can withstand operating temperatures ranging from -60° C up to +1200° C. We offer a complete range of conductor cores to suit your application which can be incorporated into our custom wire. These include nickel, nickel alloy, and plated copper. The custom manufactured wire that Dacon can provide improves quality and avoids costly complications and delays that can be caused by an ultimately incompatible or inferior product.

Chemical Resistant Wire, Chemical Resistant Cable, and Radiation Resistant Wire can also be custom manufactured to suit your requirements. HORLE Systems has extensive experience and expertise in high-performance thermoplastic insulation. We also manufacture coaxial and mini-coax cables for medical equipment applications. Custom miniature coax cable can be custom manufactured to dimensions as small as .050″.

Catheters, minimally invasive surgical equipment, endoscopes, and all kinds of medical imaging equipment require flexible wire and cable to stand up to a variety of stresses and harsh environmental conditions. HORLE Systems will custom manufacture medical wire to your specifications for maximum performance and endurance. Does your custom wire have to meet strict size, density, or flexibility constraints? Does it need to be autoclavable or to withstand other conditions related to sterilization?

Your job demands custom wire that meets precise requirements, and when you allow HORLE Systems to custom manufacture your medical wire, you know you will get the precise kind of medical wire you need.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.