In the modern world of industrial and electronic applications, accurate temperature measurement is essential. From automotive systems to medical devices, efficient temperature sensing is critical for ensuring system stability, product longevity, and safety. One of the most advanced solutions for precise temperature monitoring is the glass encapsulated NTC thermistor. Known for their reliability and exceptional performance, these thermistors play a crucial role in enhancing temperature sensing accuracy. In this article, we will explore the benefits of glass encapsulated NTC thermistors, their functionality, and how they can improve temperature sensing in various industries.

What is a Glass Encapsulated NTC Thermistor?

An NTC thermistor (Negative Temperature Coefficient thermistor) is a type of temperature sensor that exhibits a decrease in resistance as the temperature increases. These thermistors are highly sensitive to temperature changes, making them an ideal choice for precision temperature sensing.

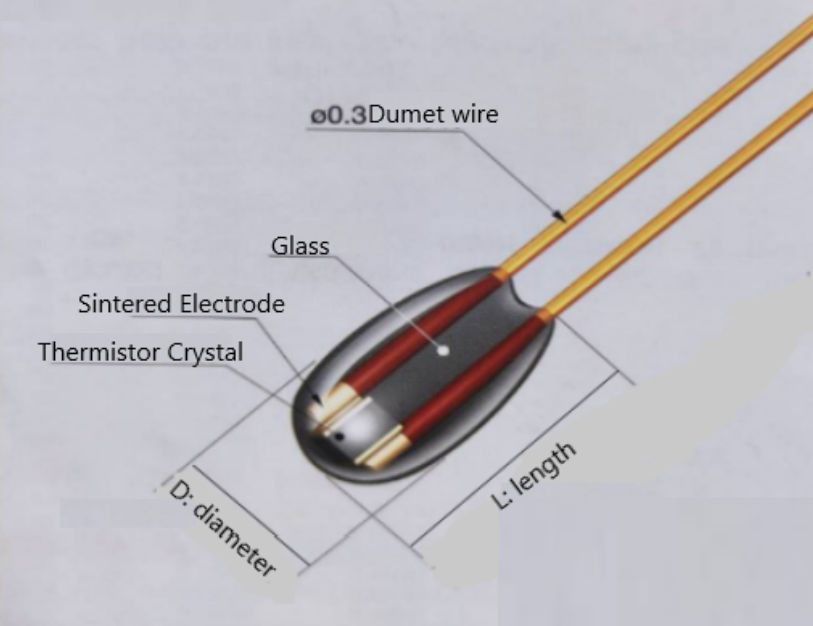

A glass encapsulated NTC thermistor is a specialized thermistor that is encapsulated in a glass shell. This design protects the thermistor from mechanical stress, moisture, and environmental contamination, ensuring longevity and consistent performance in harsh conditions. Glass encapsulation offers superior durability compared to other forms of protection, making it a preferred choice for applications requiring high accuracy over an extended period.

Key Features of Glass Encapsulated NTC Thermistors

- High Accuracy: Glass encapsulated NTC thermistors are known for their high level of accuracy, which makes them suitable for applications where precision temperature measurement is critical.

- Wide Temperature Range: These thermistors can operate across a broad temperature range, from -55°C to +300°C, making them versatile and suitable for a wide variety of industrial environments.

- Rapid Response Time: Glass encapsulated NTC thermistors respond quickly to changes in temperature, allowing them to provide real-time data that is essential for accurate temperature monitoring.

- Long-Term Stability: Encapsulation in glass protects the thermistor from environmental factors that could cause performance degradation, offering long-term stability and reliability.

- Small Size: Despite their robust design, glass encapsulated NTC thermistors are compact, allowing them to be used in space-constrained applications.

How Glass Encapsulated NTC Thermistors Improve Temperature Sensing Accuracy

Enhanced Protection and Durability

The glass encapsulation provides robust protection against various environmental factors that could negatively impact temperature sensing accuracy. Whether in harsh industrial settings or delicate medical instruments, the glass shell shields the thermistor from moisture, dust, vibrations, and chemicals, ensuring that the thermistor's resistance remains stable. This durability is key in maintaining accurate readings over time, especially in extreme temperature conditions.

Precision in Measurement

One of the key advantages of glass encapsulated NTC thermistors is their high precision. With a low tolerance and a well-defined resistance-to-temperature relationship, these thermistors provide accurate temperature readings, even in environments where slight variations can affect performance. Their ability to consistently deliver reliable data enhances system performance, as even the smallest temperature fluctuations can be detected and addressed.

Stable Resistance-to-Temperature Curve

The resistance-to-temperature characteristics of glass encapsulated NTC thermistors are highly stable. This stability translates into consistent performance, even when exposed to changes in temperature or environmental conditions. The thermistor's response to temperature is predictable, allowing for precise calibration in the system. As a result, industries relying on temperature control—such as HVAC, automotive, and consumer electronics—benefit from the thermistor's ability to accurately measure and control temperatures, improving product performance and longevity.

glass encapsulated NTC thermistor

Wide Range of Applications

The wide operating temperature range of glass encapsulated NTC thermistors makes them suitable for various industries and applications. In automotive systems, they can be used to monitor engine temperatures, ensuring that the vehicle runs within safe operational limits. In medical devices, they are used for body temperature monitoring, where accuracy and reliability are paramount. Furthermore, these thermistors are also used in battery management systems, HVAC systems, and even in food safety applications.

Quick Response Time for Dynamic Environments

Glass encapsulated NTC thermistors have a fast response time to temperature changes. This feature is crucial in systems that require real-time monitoring and adjustment. For example, in temperature-sensitive equipment like industrial machinery or medical monitoring devices, a delay in temperature feedback can lead to inefficiency, product malfunction, or even safety hazards. The rapid response time of glass encapsulated NTC thermistors ensures that adjustments can be made promptly, thus preventing any undesirable conditions from arising.

Low Power Consumption

Another key benefit is that glass encapsulated NTC thermistors operate with low power consumption, making them ideal for portable or battery-powered devices. This low power requirement helps reduce the overall energy consumption of the system, contributing to energy efficiency in the end product.

Applications of Glass Encapsulated NTC Thermistors

- Automotive Industry: Glass encapsulated NTC thermistors are used in various automotive systems, such as engine temperature sensors and battery management systems, to ensure the vehicle operates within the correct temperature range. The high accuracy and fast response time of these thermistors improve vehicle safety and performance.

- Medical Devices: In medical applications, such as thermometers and patient monitoring devices, glass encapsulated NTC thermistors offer the precision and reliability needed for accurate body temperature measurement. They are also used in respiratory devices and incubators, where temperature control is critical for patient health.

- Consumer Electronics: Many consumer electronics, including laptops, smartphones, and wearable devices, rely on glass encapsulated NTC thermistors for battery temperature monitoring and thermal management. This ensures that the devices remain within safe operating temperatures to prevent overheating and extend battery life.

- HVAC Systems: Glass encapsulated NTC thermistors are used in HVAC systems to maintain temperature stability. These thermistors help in controlling heating and cooling processes with high accuracy, ensuring energy efficiency and comfort.

Conclusion

In conclusion, glass encapsulated NTC thermistors play a critical role in improving temperature sensing accuracy across a wide range of applications. Their high precision, durability, and fast response time make them an ideal choice for industries that require reliable and accurate temperature measurements. Whether you're designing automotive systems, medical devices, or consumer electronics, the integration of glass encapsulated NTC thermistors ensures better performance, energy efficiency, and product longevity.

For industries seeking a dependable solution to temperature monitoring challenges, glass encapsulated NTC thermistors from a trusted manufacturer like Horle are an excellent choice. Horle is a leading manufacturer and supplier of high-quality glass encapsulated NTC thermistors based in China. With years of expertise and a commitment to delivering precise and reliable temperature sensing solutions, Horle offers customized thermistor solutions for a wide range of industrial applications.